2022/04/22

Dental Treatment Evolving with Digital Technology (Part 4)

The first part: Digital Technology Alliance Across Borders - Strategies for the Japanese Dental Industry

Clinical Doctor, Examination and Diagnosis, Imaging technology, Medical devices

A New Choice for Kyocera, a Japanese Medical Manufacturer

You might have heard of a dental treatment called dental implants.

That is, in which an artificial tooth root buried in the bone and a cap is attached, has become common all over the world to replace missing teeth. It is a field that requires comprehensive and advanced clinical skills in dentistry, such as oral surgery, academic knowledge of the mechanics of prosthetics (e.g., coverings), prevention, and long-term management. I thought it was a new skill that I needed to learn, so after graduating from the university, I took a training course at a university hospital and an academic society-designated course.

Digital technology seems to tend to be introduced in the United States, and under the situation of private practice (not covered by insurance) due to less restricted, even in Japan. In particular, digital technology has been actively applied in implant treatment. For example, there is a technique called “Guided Surgery,” which uses 3D images created from CT to simulate the position of the implant. "Guided Surgery" is used to avoid areas with nerves and blood vessels in the bone and take into account the bite of the final artificial tooth (superstructure).

This technology assists in making comprehensive judgments about positions that were previously calculated and determined from dental models and x-rays. Actual clinical practice cannot be done by only this kind of technology but has rapidly increased as a treatment aid tool to support the operator's experience and knowledge.

Companies supporting the dental industry are now entering the dental digital technology market in Japan. One of them is Kyocera, a manufacturer in the dental industry. The company was founded as a fine ceramics company, and today it has become a leader in high technology and solutions such as smartphones, communication terminals, and associated parts of semiconductors. Kyocera is particularly well-known for its artificial joints and bones in the orthopedic field in the medical industry.

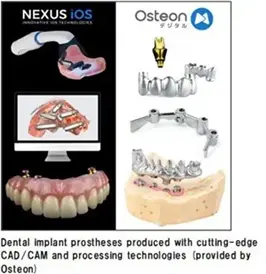

In 2021, Kyocera announced a collaboration with Osteon Digital Japan Co., Ltd.(‘Osteon’) which Osteon Medical (Melbourne, Australia) established as a manufacturing base in Japan to digitally manufacture artificial teeth (superstructure and prosthetics) to be attached to implants. In 1978, Osteon Medical launched the first dental implants (bone implants) in Japan, and now, in the digital era, the company is about to start providing new solutions.

I interviewed Mr. Toru Yoshida, General Manager, Dental Sales Department, Medical Division, Kyocera Corporation, about the past and future of the company's dental implant business and the intentions behind the collaboration.

Kamo: In the world of dentistry, where digitization is advancing, what kind of initiatives have you been taking?

Mr. Yoshida: Recently, digitalization has been progressing rapidly in the dental industry. In the dental implant business, which we are in charge of, digital technology is spreading as a matter of course, including diagnostic equipment (x-rays), simulation software for treatment, and final superstructure fabrication using CAD/CAM.

In the next article, “The second part: Digital Technology Alliance Across Borders - Strategies for the Japanese Dental Industry,” we will continue our interview on the background of the globalization of digital IT technology, the future direction of the company, and the reasons why the company decided to partner with foreign companies.

(To be continued to the next article)

【Source】

- KYOCERA Corporation Website, “Medical and Dental Products” https://global.kyocera.com/prdct/medical/

- KYOCERA Corporation News, “Collaboration with Osteon Digital Japan Co., Ltd.” August 26, 2021, https://global.kyocera.com/news/2021/0802_wjxt.html

We have not received any rewards from the publishers for writing this manuscript.

The information contained in this article is compiled by the respective authors based on publicly available information. We assume no responsibility whatsoever for any damage or disadvantage caused by actions taken based on such information. Unauthorized reproduction of articles, photos, charts, etc. is prohibited.

Copyright © 2022 LSMIP office / CM Plus Corporation

A Series of Articles